Student Projects

VE/VM450

Structure and Control of a Lifting Type Installation Plate of Refrigerator Compressor

Sponsor: Liya Wang, Jun Jiang, Midea

Team Members: Buyao Lyu, Jianing Zhang, Ziying Huang, Tingkang Wang, Ziqi Yuan

Instructor: Prof. Jigang Wu

Project Video

Team Members

Team Members:

Buyao Lyu

Jianing Zhang

Ziying Huang

Tingkang Wang

Ziqi Yuan

Instructor:

Prof. Jigang Wu

Project Description

Problem Statement

Among daily home appliances, refrigerators require compressors for cooling and freezing, thus contributing to household noise. Current solutions of sound deadening cavity or damper only deal with specific working frequencies of noise. This project is to deal with a larger range of noise by cutting the transmission of vibration from the compressor to the refrigerator body, via a lifting installation plate for compressor.

![Fig. 1 Compressor in a refrigerator [1]](https://www.ji.sjtu.edu.cn/wp-content/uploads/2020/07/450-9-pic01.jpg)

Fig. 1 Compressor in a refrigerator [1]

Concept Generation

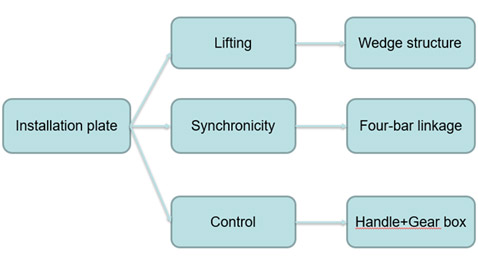

In order to allow the compressor to detach from the refrigerator body during use while connect with the body during transportation, two wedge structures with racks are driven by rotating gears through a handle.

Fig. 2 Detailed structure function

Fig. 3 Concept Diagram

Design Description

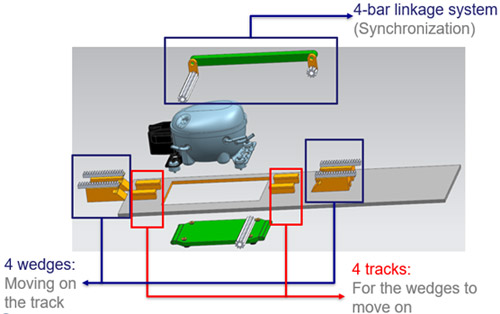

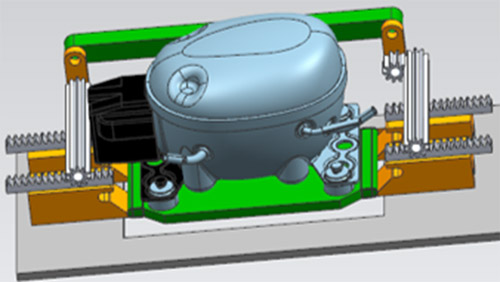

The design uses four wedges and a supporting plate to realize the lifting function. The supporting plate have two cylindrical sides that can move freely on the wedge structure. The main transmission system is a four-bar linkage which is connected to the supporting plate through gears and racks. A handle attached outside the refrigerator is then connected to the four-bar linkage and users can use it to control the compressor position.

Fig.4 The whole set-up system

Modeling and Analysis

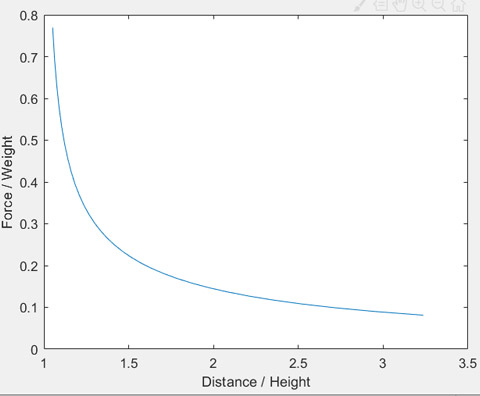

The slope angle of the wedge structure is an important parameter in our design. The force need to lift the compressor increases as the angle increases. However, the moving distance decreases when the angle increases. A balance between the moving distance and the required force is achieved at 45°as shown on the figure.

Fig. 5 2D bone profile

Validation Plan

The prototype will be validated by putting different weight on the plate to represent the compressor. We will validate the device from the following aspects:

1. Firstly, we want the weight of the prototype to be acceptable. We mainly will measure the weight of the plate.

2.Then, we would like to see if the force needed to drive the prototype is acceptable. We will measure the force needed for the operator on a certain angle when it is still.

3. Last but not least, we want to find out the tolerance of the device to any unexpected situations:

3.1 Faulty operations (Overturning, oveexerting and so on)

3.2 Displacement of the plate from the designed position.

3.3 Rotation of the plate from the designed position.

Conclusion

In this project, we firstly identified the problem to be solved: to reduce the noise produced by the compressor inside the refrigerator. The final design was chosen to be the wedge structure. The conceptual design was perfected with more details and the engineering specifications were determined. Validation of the model was also performed in terms of required force.

Acknowledgement

Sponsor: Liya Wang, Jun Jiang from Midea

Jigang Wu from UM-SJTU Joint Institute

Reference

[1]https://umjicanvas.com/files/276642/download?download_frd=1