Student Projects

VE/VM450

Design of Dynamic Bladeless Fan

Instructors: Dr. Mingjian LI

Team Members: Weihan FAN, Ding Zhe GAN, Steven Wijaya Ong, Siwei YE, Zhenting WANG

Project Video

Team Members

Team Members:

Weihan FAN, Ding Zhe GAN, Steven Wijaya Ong, Siwei YE, Zhenting WANG

Instructors:

Dr. Mingjian LI

Project Description

Problem Statement

Cooling fans have been used for a wide range of industrial applications. Bladeless fan is a novel design which multiplies the intake air by flow induction, but its applications in the industrial field hasn’t been explored much since its invention. Flow pulsation has been proved to be an efficient cooling methodology with optimal control of the pulsating pattern. This project aims to combine the bladeless fan concept with flow pulsation.

Concept Generation

The concepts can be classified into three categories: bladeless fan design, air source and pulsating system. The project uses a compressor as its air source. An electromagnetic valve along with control circuit serve as its pulsating system.

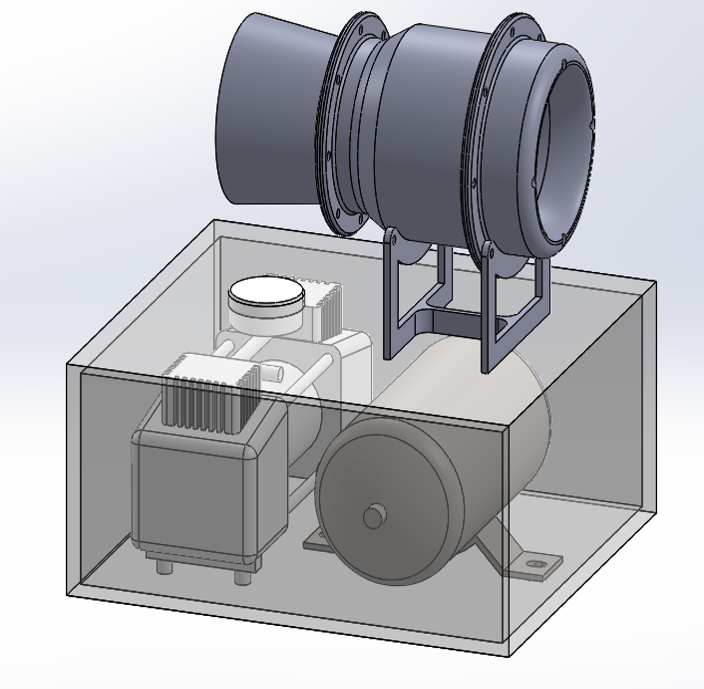

Fig. 1 Detailed structure function

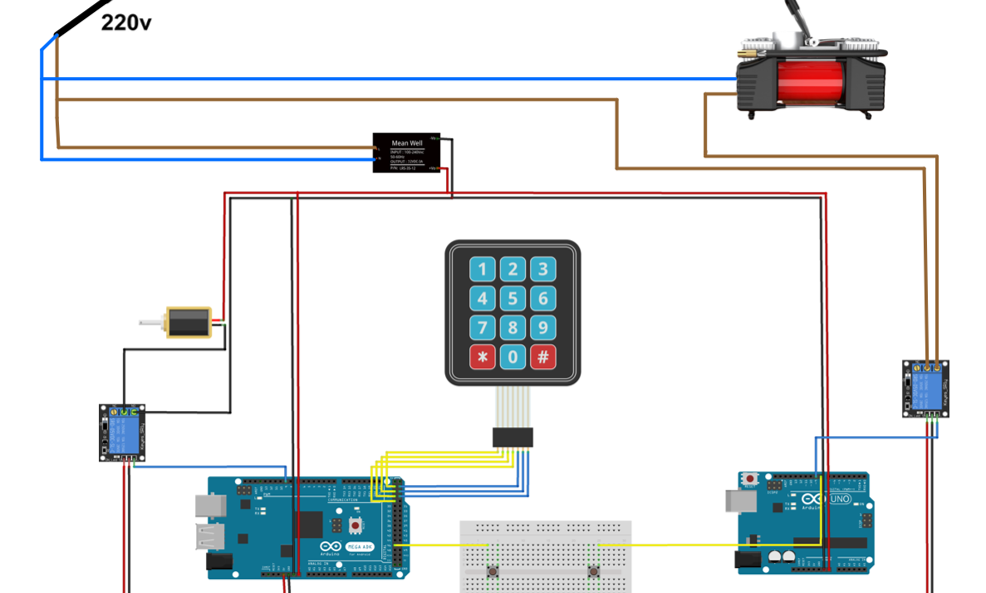

Fig. 2 Control Circuit Diagram

Design Description

When operating, an air compressor will compress the air and the high-pressure air will be sent into an air storage tank for temporary storage. The outlet of the tank is connected to an electromagnetic valve, controlled by the control circuit. The circuit will give signals to a relay, which serves as a switch for the valve. The lasting time of the opening and closing of the valve can be manually controlled by a keypad. The air will then be led into the bladeless fan design, and the airflow will be able to realize flow induction and pulsation.

Modeling and Analysis

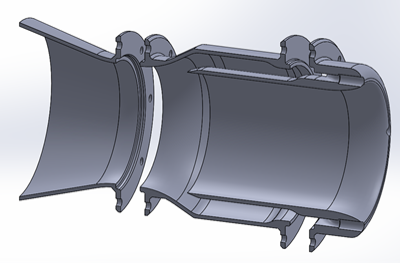

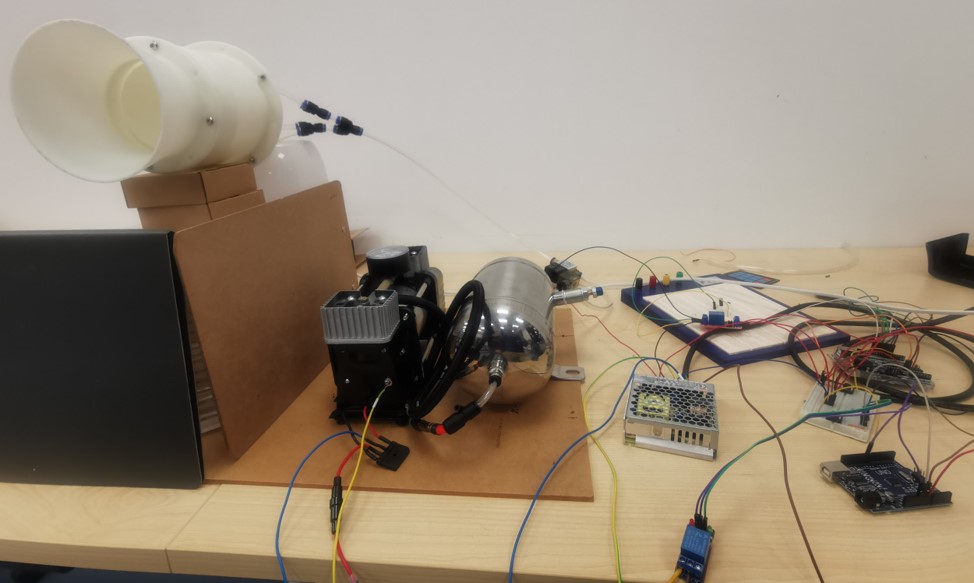

The bladeless fan is divided into three parts for manufacture. The CAD models are built in SOLIDWORKS. The figure below shows the cross section of the three components and the direction of installation. A prototype is built with a 3D-printed bladeless fan, a compressor, an air tank and control circuit elements.

Fig.3 Three part design of bladeless fan

Fig. 4 Dynamic bladeless fan prototype

Validation

Validation Process:

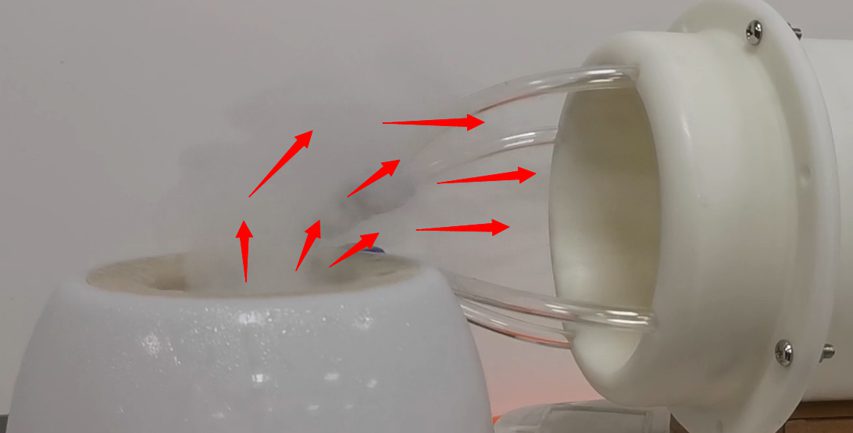

The testing of the outlet flow rate is conducted with a handheld anemometer, which measures the wind speed at the outlet of the bladeless fan. The diameter of the outlet is measured with a ruler, and the outlet volume flow rate can be estimated. The flow induction effect is visualized with a domestic humidifier. The water spray generated by the humidifier is induced by the high-pressure airflow of the fan.

The testing of the outlet flow rate is conducted with a handheld anemometer, which measures the wind speed at the outlet of the bladeless fan. The diameter of the outlet is measured with a ruler, and the outlet volume flow rate can be estimated. The flow induction effect is visualized with a domestic humidifier. The water spray generated by the humidifier is induced by the high-pressure airflow of the fan.

Validation Results:

According to validation part, most specifications can be met.

√ Fan inlet pressure >= 0.6 MPa

√ Maximum airflow rate per watts >= 0.2 L/(min*W)

√ Controllable frequency: Yes and frequency >= 10 Hz

√ Cost<= 6000 RMB

· Fan outlet flow rate

√ means having been verified and · means to be determined.

Fig.5 Visualization of airflow

Conclusion

A bladeless fan with flow pulsation is built and validated. The outlet airflow is multiplied by the fan design and the pulsating frequency is controllable. The fan airfoil design and power efficiency can be further improved.

Acknowledgement

Sponsor: Prof. Qiang Zhang from UM-SJTU Joint Institute

Mingjian Li, Jigang Wu, Chengbin Ma, and Chong Han from UM-SJTU Joint Institute

Otto Zhang from UM-SJTU Joint Institute

Mingjian Li, Jigang Wu, Chengbin Ma, and Chong Han from UM-SJTU Joint Institute

Otto Zhang from UM-SJTU Joint Institute

UM-SJTU JOINT INSTITUTE