Student Projects

VG100

Small Package-Sorting Machine

Instructors: Dr. Mian Li, Dr. Irene Wei

Team Members: Aotian Yu, Ruiying He, Tianyi Jiang, Yulin Chen, Yuxiang Chen

Project Video

Team Members

Team Members:

Aotian Yu, Ruiying He, Tianyi Jiang, Yulin Chen, Yuxiang Chen

Instructors:

Dr. Mian Li, Dr. Irene Wei

Project Description

Problem

In recent years, with the rapid growth of express delivery, it has been more and more difficult for express sorting personnel to sort and process express delivery in time and efficiently, especially on campus. This causes great trouble to students because picking up a certain package from the piles wastes time and may lead to loss and damage.

Concept Generation

Our project aims to build a small package-sorting machine, which can effectively sort different packages based on the colors of the labels attached to them. It can pick up packages from its pile and discharge them onto their corresponding shelves.

Design Description

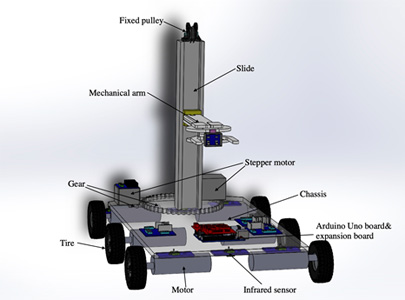

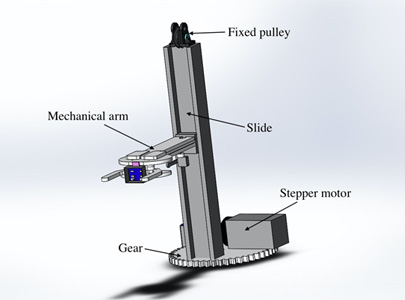

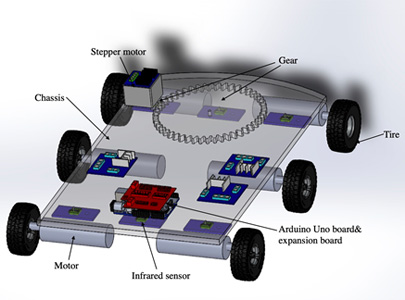

We propose a small package-sorting machine which is designed into two main parts: the vehicle body and the mechanical arm. And these two parts are supposed to implement three functions: navigation, color recognition and loading and unloading packages. So we design three systems to fulfill these function respectively. These systems work with each other to finish a whole process of package sorting. The navigating system, including wheels, motors, a line-following module and infrared sensors, helps the machine navigate along the right track. Then the color recognition system including color sensors helps it detect the colors of the labels on the packages. At last, the functioning system, the main part of which is the mechanical arm, picks up the package and discharge it to the right place.

Fig. 1 The concept diagram of the machine

Fig. 2 The mechanical arm part

Fig. 3 The vehicle body

Modeling and Analysis

The way to realize our project is mainly divided into four parts. Firstly, to achieve the navigating system, we assemble the infrared sensor onto the chassis which has been equipped with wheels, motors and Arduino Uno board beforehand. Then to achieve the functioning system, we design the mechanical arm and assemble it along with the stepper motor and the servo. Next, to achieve the color recognition system, we install the color sensor onto the mechanical arm. Finally, we simulate a setting with complex terrain and assign the machine with several tasks to analyze its efficiency and accuracy.

Validation

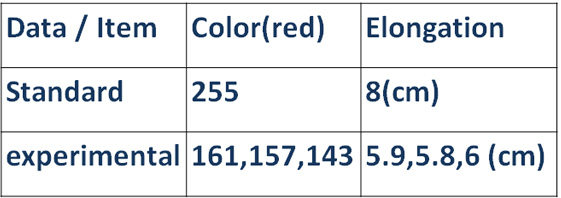

We did a sample test by testing our machine’s mechanical arm’s elongation length and color recognition function.

We list two experiments in Table 1 just as an example. By comparing the standard value and the data we get, we find that our machine can recognize color within certain scale and extend its arm to some length. Our machine has the foundation to achieve its function, but for accuracy, we need to test and modify more.

Table 1: Sample Test Data

Conclusion

The project provides an economical and flexible alternative to traditional automatic sorting system. It can accurately implement functionality of sorting, loading and discharging, which makes it possible to realize package-sorting on campus. However, it still has some limitation for it can only achieve sorting based on colors of the labels on the packages and the capacity of the machine is limited. Overall, though this machine is only a prototype, it can effectively actualize small-scale package-sorting.

Acknowledgement

Dr. Mian Li and Dr. Irene Wei from the UM-SJTU Joint Institute;

Teaching Assistants [Fubo Qi, Hanyang Feng, Sheng Qiao, Xiaoxuan Wang] for VG100 at UM-SJTU Joint Institute.

More project information, please contact: [atyu328510@sjtu.edu.cn]

Teaching Assistants [Fubo Qi, Hanyang Feng, Sheng Qiao, Xiaoxuan Wang] for VG100 at UM-SJTU Joint Institute.

More project information, please contact: [atyu328510@sjtu.edu.cn]

UM-SJTU JOINT INSTITUTE