Student Projects

VG100

Green Cooling Cup

Team Members: Chodchanit Jirapavasuti, Jingnan Gao, Xiaochen Zhao, Zhijun Bian, Zhujiang Gu

Project Video

Team Members

Team Members:

Chodchanit Jirapavasuti, Jingnan Gao, Xiaochen Zhao, Zhijun Bian, Zhujiang Gu

Instructor:

Dr. Qiang Zhang, Dr. Irene Wei

Project Description

Problem Statement

“More than 80% of people experienced scald burn from drinking and serving hot beverages” (Hot Food and Beverages Can Burn!, 2020). Cooling cups sold on the market can prevent this by taking less cooling time, but they consume external electricity. The purpose of this project is to create an eco-friendly product that can cool down hot water without consuming external energy.

Design Concept

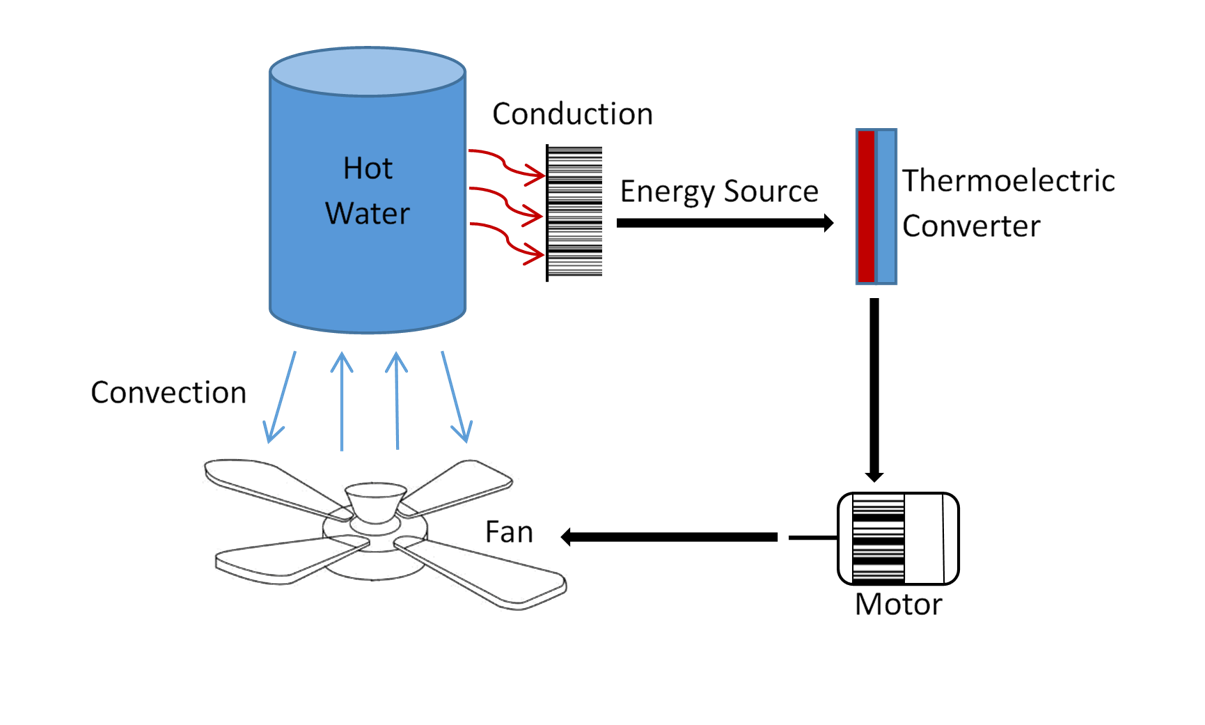

- Heat conduction occurs between the cup and TE modules due to temperature difference.

- Thermoelectric converters are used to convert the thermal energy of hot water into electricity to run the fan.

- The fan drives the heat away from the heat sinks to maintain the temperature difference between the two sides of the TE modules.

Fig. 1 Concept Diagram

Cooling System

- Energy supply system : TE modules and heat sink work as the electric source of the cooling system.

- Axial fan: 15:8 Ellipsoidal fan tail is designed to reduce the separation of the boundary layer and make the wake as smooth as possible.

- Guide vane: Six straightening vanes are placed at the bottom of the cup to turn the wind direction to be parallel to the channels of the heat sink, which can minimize friction loss of wind and increase heat convection.

Fig. 2 Solidworks 3D Model

Fig. 3 The cooling system

CFD Simulation

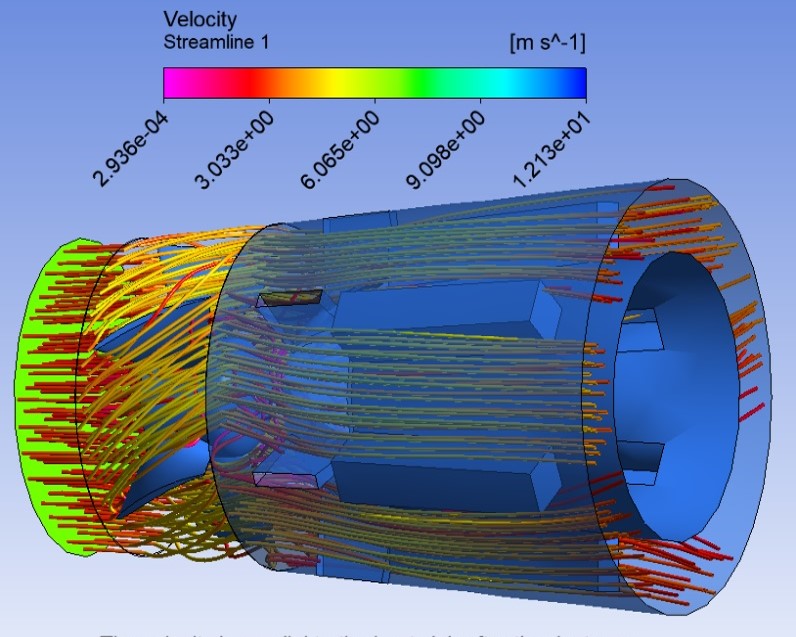

The velocity streamline is produced in the ANSYS 2020 simulation to visualize the velocity. The result indicates that the duct vane changes velocity‘s direction so that it becomes parallel to the heat sinks, which makes the outflow of air more stable and stronger.

Fig. 4 Streamline colored by velocity

Performance Measurement

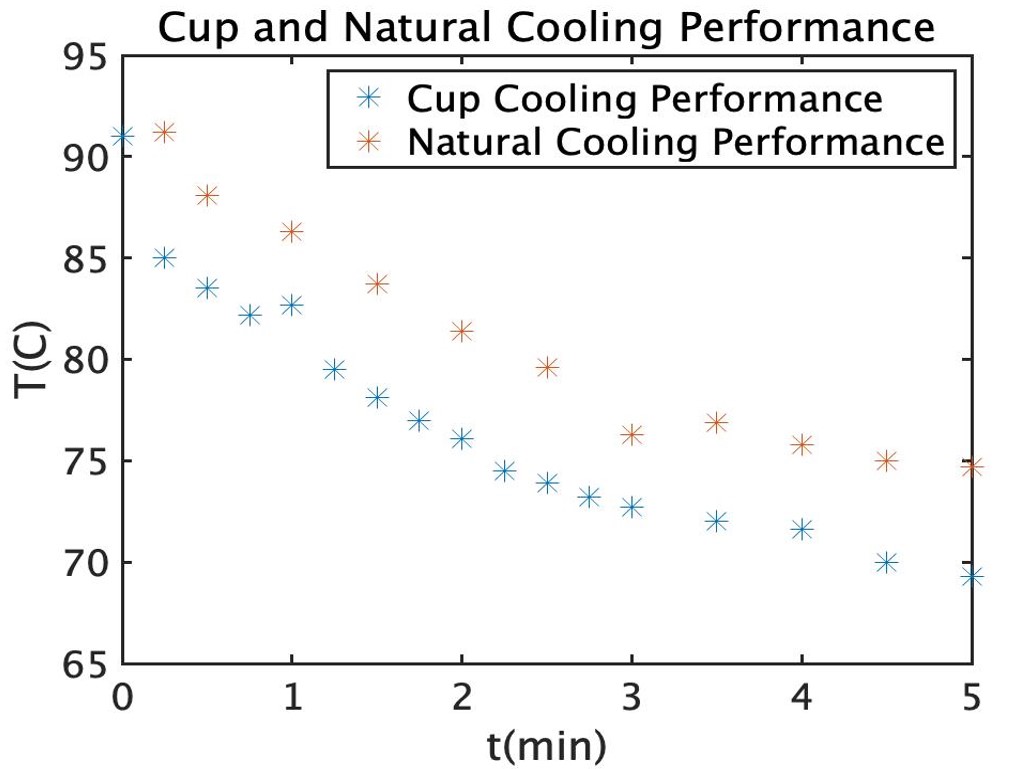

As shown in Figure 5, the cup can cool down hot water much faster than natural conditions, but the cooling process slows down after 3.5 minutes. This is because the increasing temperature of heat sinks leads to a smaller temperature difference between the two sides of TE modules, which generates lower voltage output.

Fig. 5 Cooling performance

Conclusion

Our green cooling cup can cool hot water down quickly with no external energy, making it environment-friendly and portable. Optimized with 15:8 ellipsoidal tail and duct vane as well as a stable structure design, the entire integrated system is able to achieve satisfactory performance. The system may be improved by enlarging the temperature difference between the cup and the heat sink after the first few minutes.

Acknowledgement

Instructors: Dr. Qiang Zhang and Dr. Irene Wei from SJTU Global College.

Teaching Assistants: Haonan Luo, Shijie Zhong, Xingye Tang and Minjia Qian from SJTU Global College.

Reference

[1]https://www.dshs.wa.gov/sites/default/files/DDA/dda/documents/Caregiver%20Alert%20Template%20-%20Hot.pdf