Student Projects

VG100

Green Cooling Cup

Sponsor: UM-SJTU Joint Institute

Instructor: Prof. Qiang Z.& Irene W.

Team Members: Ke Chen, Xuzhong Chen, Yining Sun, Yining Xie, Wentao Xu

Project Video

Team Members

Team Members:

Ke Chen, Xuzhong Chen, Yining Sun, Yining Xie, Wentao Xu

Instructor:

Prof. Qiang Z.& Irene W.

Project Description

Problem Statement

Environmentalism has gone viral nowadays. So, being green has become one of the core requirements for customers. However, all the

existing cups in the market rely on external electricity. This project’s objective is to design a cooling cup that does not consume extra energy and can effectively cool down the hot water.

Fig.1 A cooling cup on the market driven by electricity [1]

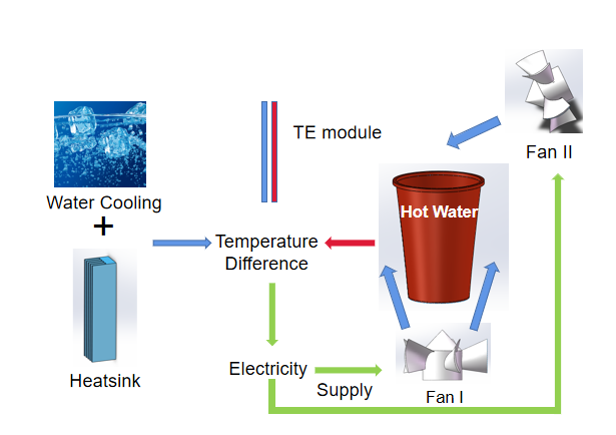

Design Concept

- The thermoelectric (TE) generator module use temperature difference to create electrical energy. It can be used as a substitute for external energy to run the system.

- Water cooling can be used to keep the temperature difference.

- According to [2], a study about systems with small scale of heat transfer, air cooling is the best choice of cooling systems in such small systems.

- When designing the fan, the performance needs to cater to the given rotors, energy and other factors. It optimizes the direct cooling effect on the water.

Fig.2 Concept diagram

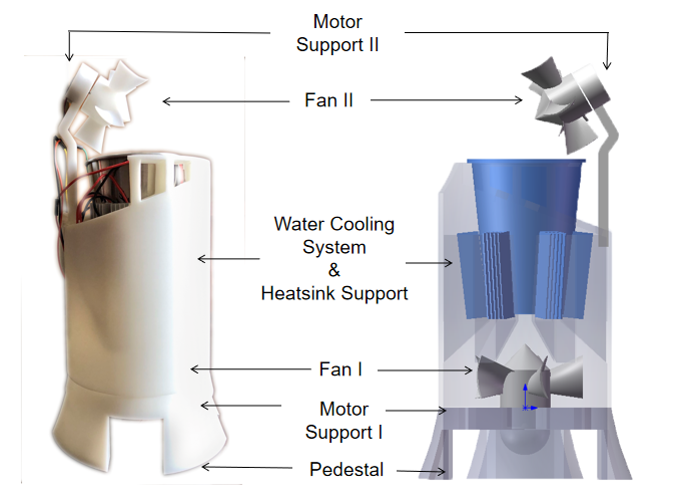

Cooling System

- Fan Design Conical head structure is designed to reduce separation and hollow strucure to reduce weight.

- Two Fans Structure: Two fans in parallel are designed to cool the water from two different directions. The flows from two directions won’t interfere with each other.

- Water Cooling System: Water cooling system is designed to enlarge the temperature difference between two sides of the TE modules so more electricity can be generated.

Fig.3 Overall system design

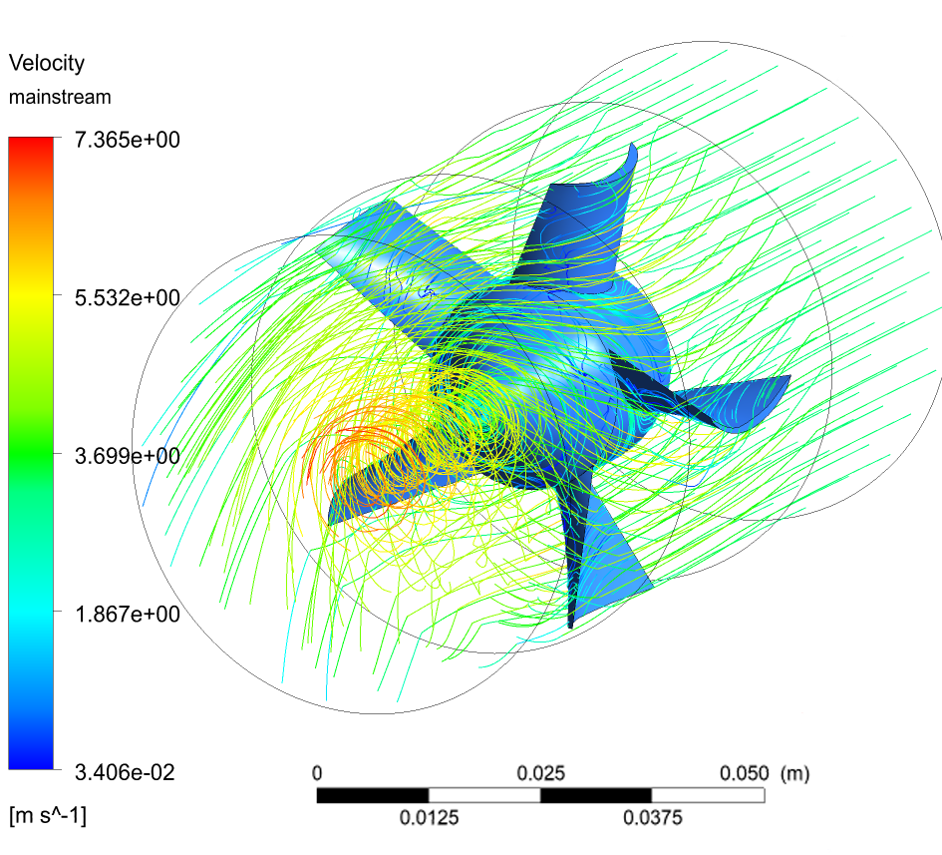

CFD Simulation

The fan shape is generated according to the speed, temperature and other parameters. An Ansys simulation is made to visualize the performance. The results shows that the fan produced a smooth airflow

Fig.4 Velocity field in a pipeline generated via Ansys

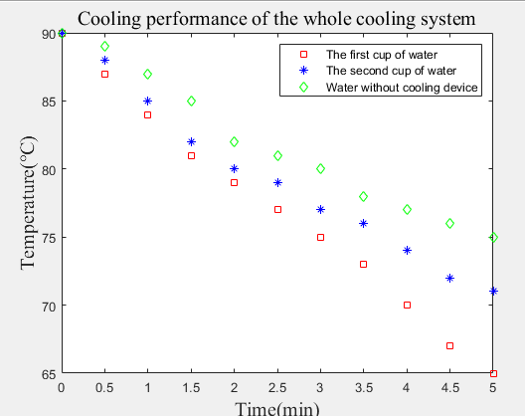

Performance Measurement

The result of the cooling performance, as shown in Figure 5, shows that in 5 minutes, the temperature drops from 90℃ to 65℃, while the temperature only drops to 75℃ in natural condition. so this shows that our cooling system do can save customers’ waiting time. But the cooling effect will reduce if customers add a second cup of water immediately. The temperature will drop to 71℃ in five minutes.

Fig.5 Overall Performance of the whole system

Conclusion

- In this project, a cooling cup without external energy consuming is designed. It can save the cooling time up to 5 min.

- Two-fan system adds temperature decline of water by 5℃ and doesn’t have a noticeable negative effect on time of operation.

- Water cooling significantly increases the initial voltage.

Acknowledgement

Prof. Qiang Zhang and Irene Wei from UM- SJTU Joint Institute, Shijie Zhong, Haonan Luo, Otto Zhang

Reference

[1]https://item.taobao.com/item.htm?spm=a230r.1.14.20.159a6eb1Xfl74R&id=620152750846&ns=1&abbucket=9#detail

[2] Xiao H., Shi Y., Xu Z., et al. Study on flow and heat transfer of small scale gas flow for air cooling system. Int. J. Precis. Eng. Manuf. 16, 2491-2498 (2015).