Student Projects

VE/VM450

Wireless Charging System in Factory

Instructors: Dr. Mingjian Li

Team Members: Yihang Xu, Yimin Jiang, Jiahao Sun, Haoyang Chen, Bicheng Gan

Project Video

Team Members

Team Members:

Yihang Xu, Yimin Jiang, Jiahao Sun, Haoyang Chen, Bicheng Gan

Instructors:

Dr. Mingjian Li

Project Description

Problem Statement

A majority of factories nowadays use electric vehicles(EVs) as carriers. However, most EVs are driven by human which leads to high labor cost and safety issues. Besides, the EVs are charged through wires manually, making it inconvenient for users to operate. This project aims to solve these problems, designing:

- A wireless charging module for electronic vehicle models.

- A route planning system based on factory layout which enables EVs to drive autonomously.

Concept Generation

- Hardware: Concerning the tradeoff between charging efficiency and technical difficulties, magnetic induction is selected as the concept to implement the wireless charging module.

- Software: A* algorithm is chosen as the route-planning algorithm to utilize in the software simulation. Unity is selected as the software for visualization since it supports 3D model display and programming language C#.

Fig. 1 Wireless EV Charging System[1]

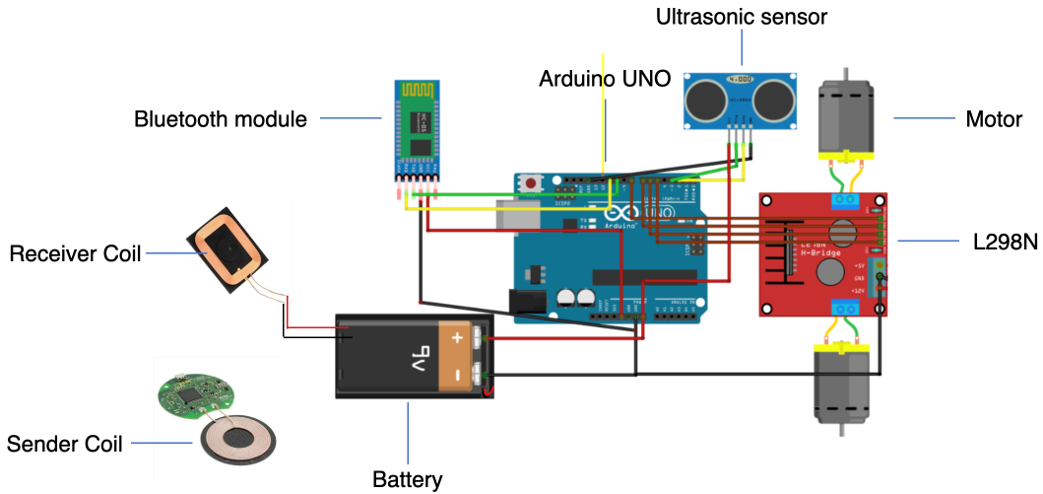

Fig. 2 Concept Diagram of the Model EV

Hardware Design

The model EV mainly consists of motors, sensors, an Arduino UNO board and a wireless charging module. The module includes:

- A transmitter in the charging pile

- A receiver installed on the EV

- Battery on the EV

- The EV is supposed to:

- Perform line-tracking.

- Stop and start charging when it detects a wireless charging pile.

- Restarts after sufficiently charged.

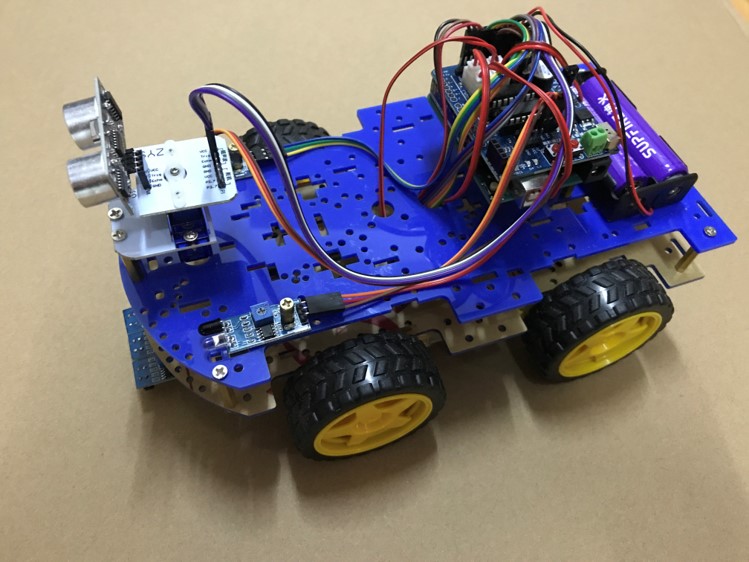

Fig.3 Model EV

Software Simulation

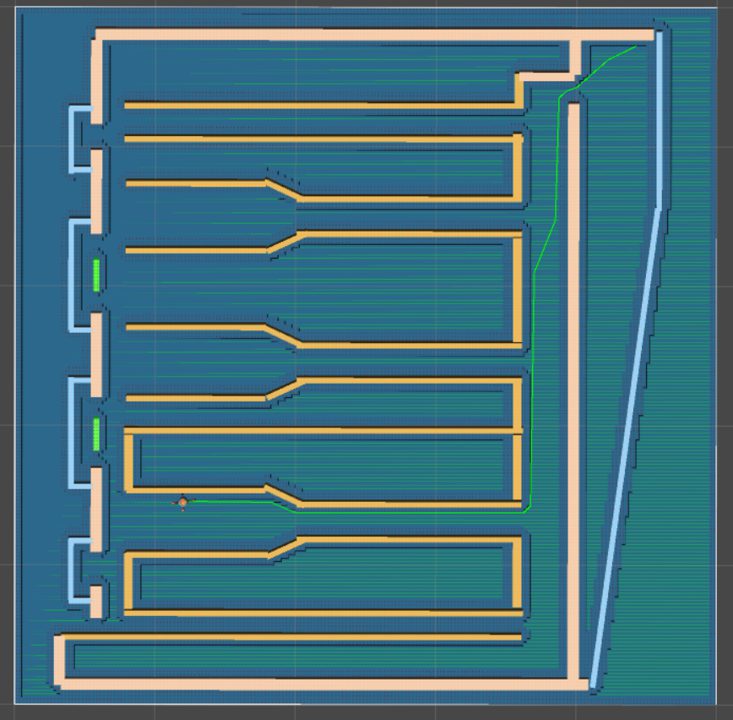

Algorithm visualization is conducted in Unity, a 3D game engine. Factory layout is reconstructed according to the architectural drawing provided by our sponsor. Given a destination, the program repeats the following steps if new obstacles are detected on path or the EV runs out of power:

- Runs A* algorithm to find the optimal path.

- Applies post processing techniques to smooth the path.

Fig. 4 Factory Layout Simulation in Unity

Validation

Validation experiments conducted:

1. Hardware:

1. Hardware:

- Wireless charging test (measuring the charging efficiency)

- Accuracy test (measuring the distance between the centers of wireless charging pile and receiver on the EV when charging)

- Line-tracking test (if the EV tracks the line)

2. Software:

- Collision test (between EV and obstacles)

- Algorithm average run time

- Restriction area test (EV should not path through restricted areas in factory)

Validation Results:

√ Charging efficiency >= 70%

√ Charging Time <= 30min

√ Inducing Distance < 3cm

√ Location error < 5mm

√ Algorithm run time < 150ms

√: verified design specifications

Conclusion

This project puts forward an idea that wireless charging and autonomous driving can be combined and applied to factories to solve existing problems. With the rapid development of wireless charging EV and artificial intelligence, it is possible that this idea will be applied to real factory settings in the near future.

Acknowledgement

Sponsor: Yazhou Wang from Penya Intelligent Technology

Dr. Mingjian Li from UM-SJTU Joint Institute

Dr. Mingjian Li from UM-SJTU Joint Institute

UM-SJTU JOINT INSTITUTE