A Capstone Design project conducted by five Class of 2025 undergraduate students at Shanghai Jiao Tong University Global College (SJTUGC, abbreviated as GC) has been selected as one of the global top three finalists for the 2025 Grundfos Prize Student Award. The project, “AI-driven Liquid Cooling System Management,” was chosen from 39 submissions across eight countries and featured at an international cooperation and innovation exhibition.

The project applies artificial intelligence to enhance monitoring and predictive maintenance capabilities in liquid cooling systems, aiming to support energy efficiency and green industrial transformation. Representing the team, Tianxiang Li and Lingbo Duan were invited to attend the award ceremony and related innovation activities at Grundfos global headquarters in Bjerringbro, Denmark.

Tianxiang Li (first from left) and Lingbo Duan (second from left) attend the award ceremony

Tianxiang Li (first from left) and Lingbo Duan (second from left) attend the award ceremony

Grundfos, a world-leading pump solutions provider, has partnered with GC to integrate real industrial challenges into the College’s engineering education through joint Capstone Design projects. The award-winning project was co-supervised by GC faculty member Professor Chengbin Ma and Grundfos mentor Dr. Cheng Qiao. Focusing on the health monitoring and predictive maintenance of liquid cooling systems, the project seeks to reduce energy waste, improve operational reliability, and explore intelligent solutions for sustainable industrial maintenance. This collaboration enables students to work in an industry-facing international environment, strengthening their innovation capability and practical engineering skills.

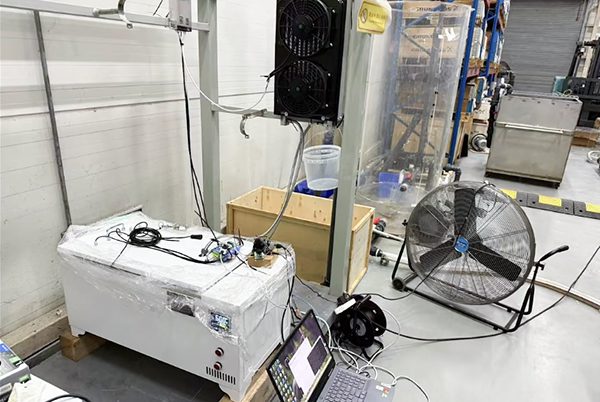

In response to key industrial needs such as energy efficiency, low maintenance costs, and sustainability, the student team applied Quality Function Deployment (QFD) methods taught in the Capstone curriculum to align system indicators with Grundfos’s sustainability strategy. To address the common challenge of limited fault data in industrial scenarios, the team built an experimental platform simulating real pump cooling systems, collecting multisource sensor data and generating degradation curves through accelerated testing for model development. The team developed an unsupervised LSTM anomaly detection model and a supervised CNN-LSTM hybrid prediction model. These models evaluate pump health conditions and predict coolant life under limited data availability, demonstrating solid performance in multiple simulated fault conditions. After three months of testing and validation, the final solutions were recognized by the corporate partner for their technological relevance and practical value.

Prototype of the “AI-Driven Liquid Cooling System Management” Project

During their visit to Denmark, the GC students exchanged insights with peers from around the world and presented their work at the international exhibition. Through activities such as factory tours and innovation workshops, they gained exposure to Denmark’s industrial ecosystem and observed the integration of precision manufacturing, automation, and green technologies.

Award-winning student representatives participate in innovation exchange activities at the Grundfos headquarters.

The project represents a strong example of GC’s university–industry joint Capstone Design model. Over the years, GC has established partnerships with more than 300 enterprises and developed nearly 600 joint Capstone topics. By bringing real-world industrial scenarios into the classroom, the model allows students to engage in the full research and development process—from needs assessment and solution design to prototyping, testing, and final presentation. This approach supports GC’s efforts to cultivate future-ready engineering talent with global perspectives and practical innovation capabilities.

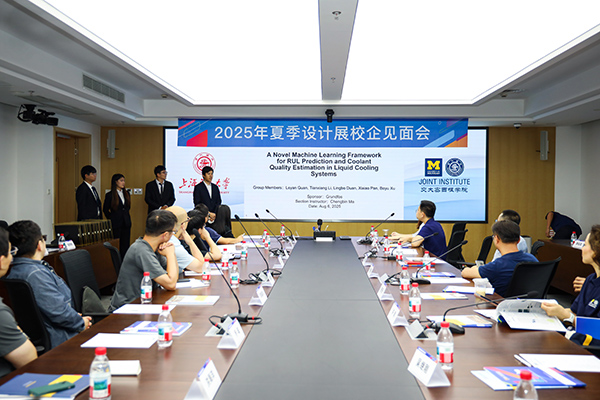

The GC student team share their project outcomes at the 2025 Summer Design Expo with enterprise representatives.