The University of Michigan-Shanghai Jiao Tong University Joint Institute (UM-SJTU JI, JI hereafter) 2021 Winter Design Expo opened on December 15 at Long Bin Building, displaying 47 innovative design projects from a number of autumn experimental courses of freshmen and senior students including “Introduction to Engineering” and “System Design and Implementation”. Online live broadcasting was set up in which two JI broadcasters introduced the exhibition and showed the students’ design works in the building.

Unmanned intelligent technologies have not only reshaped traditional industries, but also changed the ways of human life. The JI design expo projects serve to encourage students to find problems from life and work out creative solutions by using what they have learnt from classes.

Sky Climber

Rapid development of express mail or courier service has brought great convenience to people’s life. However, picking up the delivery can still be a pain to old and weak people or people with poor ability to walk. The Sky Climber project team of freshman students worked out a courier service robot capable of accomplishing three functions: climbing upstairs with adaptability to different stair heights, putting down the packages and alarming the surrounding people to avoid being stepped.

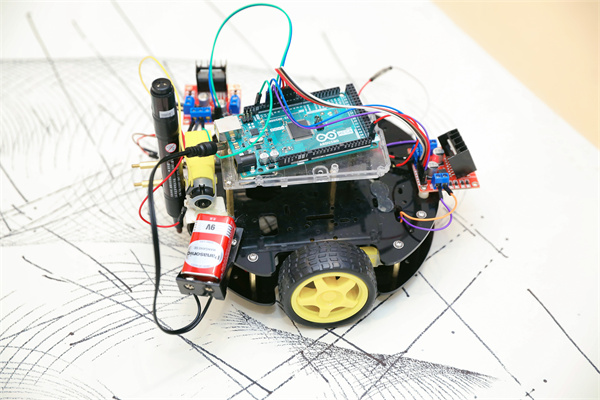

Quick Sorting Delivery Vehicle

Fast expanding of online shopping has led to the rapid development of logistics industry. However, the efficiency upgrading of package sorting and delivery fails to meet the increasing demand for package sorting and delivery. The existent courier sorting and delivery model using large logistic machines or human workers has several drawbacks: low mobility and large space occupation of the machine, high cost of the machine purchase and maintenance and worker’s salary. The Quick Sorting Delivery Vehicle project team of freshman students designed a flexible, compact and economic vehicle for package sorting and delivery. The vehicle consists of automatic moving system, package identification system and delivery system. The automatic moving system can help the vehicle to avoid the obstacle in the courier station and guide it to deliver packages in an appointed route, hence enhancing its mobility and stability; the package identification system detects the information of the packages, which contains the destination of different packages’ delivery; the delivery system is embedded in the vehicle, reducing the space occupation.

As the world experiences a new round of science and technology revolution and industry reform, it also faces a series of challenges such as global climate change and power shortage. How to make effective use of energy and promote the diversified development of renewable energy is also a focus of JI students.

Wave Power Generator

Although the GPS system has been widely put into use, there are still many sea islands where electricity could hardly be generated because of poor infrastructure and their remoteness. Fishermen passing by these islands will face difficulties in finding their way home and boats passing by will have trouble avoiding running on rocks. The Portable Low-cost Wave Power Generator Based On Point Absorber Buoy Model project team of freshman students came up with a solution to generate power using wave energy, which is a kind of underdeveloped green energy. Compared to solar and wind power generator, the JI student product can generate electricity whenever it’s rainy or windy, dark or light.

Rowing Machine Generator

Bodybuilding has become an indispensable part of life for many people. As people work out at gym, they probably don’t realize much energy is wasted during the exercises. The Rowing Machine Generator project team of freshman students came out with a solution to convert energy wasted during workouts into electricity. The rowing machine generator is made of three parts: rebounding system, transmission system, and generating system. Rebounding system gives the user the experience of working out on a rowing machine, namely using power when pulling chains and relaxing when the chain is pulled back. During workouts, the flywheel is driven to rotate, and the rotating is transmitted and accelerated by transmission system to drive the generator. In the generating system, electricity is generated and then rectified by a rectifier. After the current and voltage is measured and displayed by a monitor, it will drive two fans, which not only breezes are produced to make user cool down, but it also gives the user a sense of accomplishment.

Onsite scenes of design expo

Since the inception of corporate-sponsored projects at JI in 2010, more and more multinational companies have been wooing the talented JI students to work on their market-oriented projects. The 2021 design expo attracted representatives from companies including General Motors, Shanghai Nio, VMware, AIMS, Shanghai Newrizon and Beijing BuilderX. In meeting with JI faculty and administration, they expressed strong interests to continue collaboration with JI in the areas of capstone design, research cooperation, employment and internships, scholarships and career development guidance. The design expo provides students opportunities of real-life engineering practices and stimulating creative thinking, through various measures such as course introduction and enterprise-institute exchange. It also provides a comprehensive and multi-channel platform for JI to explore talent cultivation and cooperation with enterprises.

Energy Control Optimization on a Simulation Platform

With the rise of unmanned driving, the energy consumption of unmanned driving has become the next industry concern. Especially for pure electric vehicles, optimizing energy consumption by 5% can save huge energy expenses and increase battery life for thousands of kilometers of driving. However, conducting such optimization tests on the road requires a lot of time and money to collect data over and over again. The Energy Control Optimization on a Simulation Platform project team of senior students provided work including the development of randomly sampled curvature and connection topology to generate road networks to improve the agent’s adaptation to different road conditions. The algorithm also focuses on optimizing energy consumption while ensuring safety, so the final comparison will be a weighted average of the two.

Excavator Bucket-fill Factor Detection Prototype

In order to save manpower cost and improve operation accuracy, automatic refit has become the mainstream trend of construction machinery development. As the most representative construction machinery, the automatic refit of excavator is essential. The Excavator Bucket-fill Factor Detection Prototype project team of senior students sponsored by BuilderX carried out a research and worked out a demonstration consisting of two parts: the simulation of the physical model of the excavator bucket and the core code of data analysis. It works like this: the material is placed in the bucket, and then the bucket is rotated to a specific position. Depth cameras record photos and 3D point clouds of the material, and then analyze the type and volume of the material to estimate further parameters like mass as needed. The research finds the volume judgment error rate of dense material like corn is less than 10%, and the volume judgment error rate of non-dense material like stone is less than 20%. The running time of background analysis is less than 1 second, and the equipment can realize continuous detection.

Award ceremony of the winter design expo